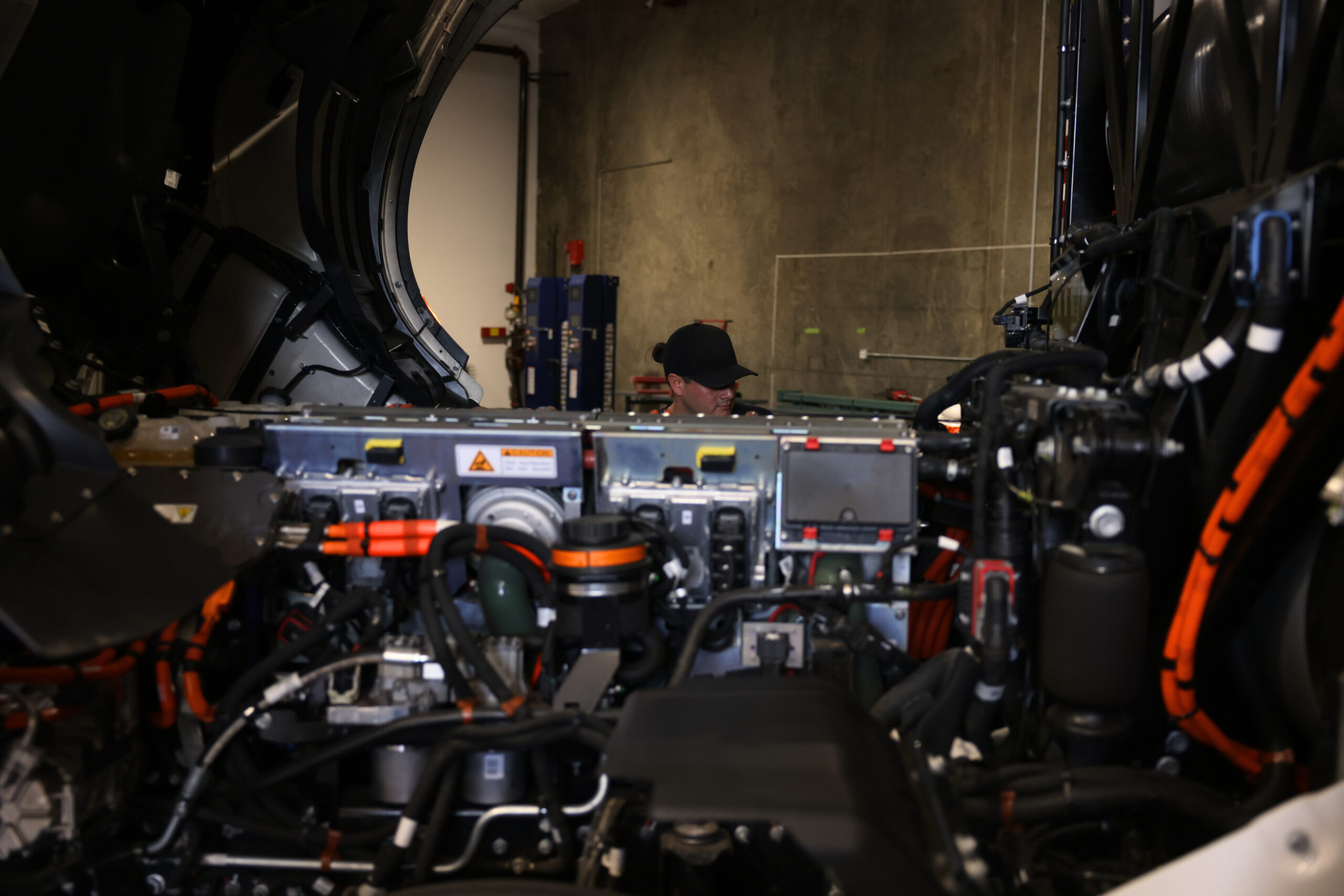

As EV trucks become more prevalent, maintenance education is a crucial component for ensuring safety in the service bays. These high-voltage systems present unique challenges that require specialized training, procedures, and equipment. It’s critical to remain aware of some key requirements for safely servicing electric specialty and vocational vehicles:

1. Implement Workplace Safety Controls

Implementing robust safety measures in your service bays is essential when dealing with high-voltage EV systems that can exceed 700 volts. Key steps to creating and ensuring a safe workspace include:

- Clear Signage: Prioritize making employees and visitors aware of areas with high-voltage systems with hard-to-miss warnings and notifications.

- Safety Stanchions or Curtains: Establishing a clear boundary around high-voltage areas prevents unauthorized access and helps control the work area.

- Shepherds’ Hooks: These simple, non-conductive tools are vital for safe rescue operations in case of high-voltage contact incidents. Their use protects the rescuer from receiving the same shock the victim may be experiencing.

- Certified Equipment and Training: Always use equipment that meets OEM standards, and be sure employees are trained in proper regulatory certifications, like the NFPA 70E for arc flash safety. Note that the OEM may only certify trained individuals to bring down high voltage systems in an authorized service environment, such as a dealer or fleet-controlled EV repair bay. Doing so without certification may void your factory warranty.

- Emergency Response Training: Crash procedures should be well-documented and rehearsed to minimize risks. Responders should also be knowledgeable about personal protective equipment (PPE).

2. De-energize Vehicles Before Service

Before servicing any high-voltage component, you must ensure that the vehicle is de-energized. Critical de-energization practices to implement into your team’s routine include:

- Lock-Out/Tag-Out (LOTO): Implement a strict LOTO protocol for main battery disconnect (MBD) to prevent accidental re-energization during servicing.

- Wait 15 Minutes: After de-energizing, allow enough time for residual charges to dissipate before proceeding. Testing the charge port with a 1000V metrawatt multimeter and documenting readings ensure that the vehicle is safe for hands-on work.

3. Wear Personal Protective Equipment (PPE)

Wearing the correct PPE is essential when servicing electric vehicles. Ensure that you and your technician teams are equipped with and trained in the appropriate use of PPE, including:

- Class 0 High-Voltage (HV) Gloves: Technicians should wear gloves rated for high voltage and conduct daily pump tests to ensure that they are in proper condition.

- Arc Flash Suit and Bump Cap or Hard Hat: Wearing an arc flash-rated suit and headgear protects against potential electrical explosions.

- EH-Rated Safety Footwear: Non-conductive, EH-rated safety shoes minimize the risk of electric shocks.

- No-Metal-Jewelry Policy: Enforce a strict no-metal-jewelry policy. Even small metal objects can conduct electricity, posing significant risks in a high-voltage environment.

4. Understand Vehicle-Specific Procedures

Understanding the specific safety procedures for electric vehicles is vital. ETHERO advises technicians to be familiar with:

- Hazardous Voltage Interlock Loop (HVIL): Knowing how to properly disable this safety feature is crucial before initiating repairs.

- Manual Service Disconnects (MSDs): Always keep “dummy” MSDs on hand and ensure that the vehicle has one installed for safe maintenance.

Ensuring service safety for electric commercial vehicles demands a thorough understanding of high-voltage risks, de-energizing procedures, and proper protective equipment. By following these expert recommendations, technicians can maintain safety and ensure that repairs are performed efficiently and securely.

Do you need service for one of our trucks or have questions about zero-emissions vehicle maintenance? Contact 804.823.1280 or info@ethero.com to speak with someone on our team.